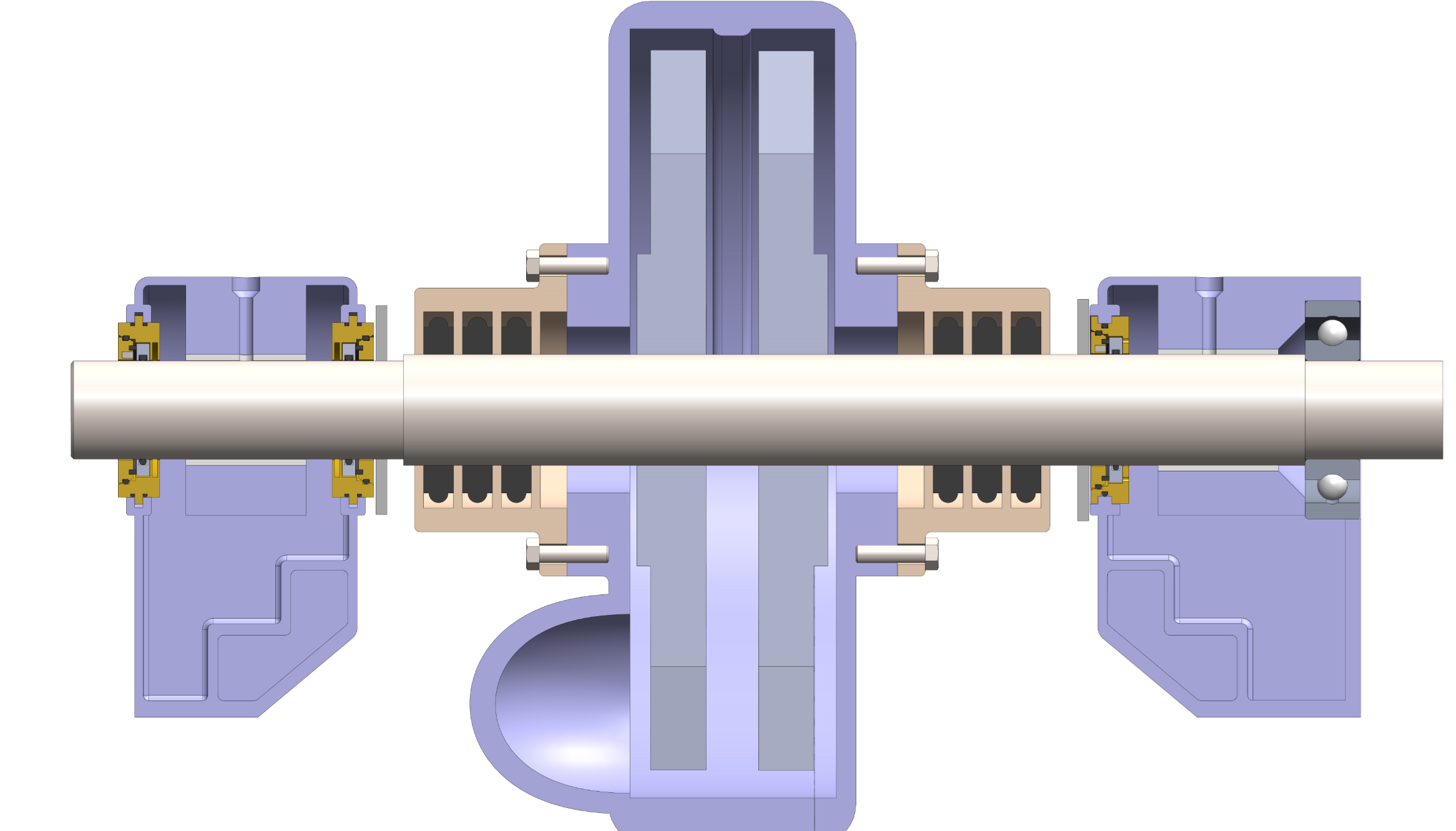

When bearing isolators are used in place of lip seals the repair, replacement and downtime costs for rotating equipment decreases substantially. The Society of Tribologists and Lubrication Engineers (STLE) and the National Research Council of Canada (NRCC) estimate that 82% of machine wear is caused by particle contamination. Unlike labyrinth bearing isolators which are non-contacting devices, IsoMag magnetic bearing isolators provide a positive seal that prevents leakage, protects against the ingress of internal contamination, and provides years of reliable service. WHAT IS DIFFERENT ABOUT ISOMAG MAGNETIC BEARING ISOLATORS? With a more effective bearing lubrication containment, as well as enhanced protection from external contamination end-users achieve an improved MTBR. However, IsoMag magnetic bearing isolators now provide a superior technology. Straight labyrinths are still used in many pieces of rotating equipment in the O&G and petrochemical and power industries such as pumps and steam turbines. Due to the elastomeric material running against a metallic rotating shaft, the lip seal can also damage the shaft. In virtually all rotating equipment applications lip seals lose their functionality within six months. In most of these applications the performance of these devices fails to meet today’s MTBR objectives. Today a wide variety of rotating equipment still uses lip seals or dual labyrinths to contain and protect bearing lubrication. Before bearing isolators, most rotating equipment bearings were protected with rubber lip seals or stationary labyrinths. It does not store any personal data.WHAT ARE BEARING ISOLATORS AND WHY ARE THEY USED?īearing isolators provide containment and protection from external contamination for bearing lubrication. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. The cookie is used to store the user consent for the cookies in the category "Performance". This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other.

The cookies is used to store the user consent for the cookies in the category "Necessary". The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional".

The cookie is used to store the user consent for the cookies in the category "Analytics". These cookies ensure basic functionalities and security features of the website, anonymously. Necessary cookies are absolutely essential for the website to function properly. DMR Bearing Isolators can normally replace existing sealing devices, without modification to the equipment.Įxtending equipment operating life across these industries: The use of alternative PTFE fillers extends the physical properties and capabilities into such areas as food production and pharmaceuticals. High-grade PTFE composites in the construction of the standard bearing isolator range ensure a wide range of operating capabilities, including high and low temperature and extreme chemical environments. Applications with pressurized, flooded, or sealed bearing housings can now benefit from Types FS and FN, which feature an internal lip seal, again offering benefits of zero leakage and zero entry of contaminants.

The product range Bearing Isolator ProTech consists of a complete family of complementary designs that provides outstanding performance for virtually any application. The DMR Bearing Isolator is based on a simple, unitized, two-piece design normally manufactured in chemically resistant PTFE. Surveys have shown that even a tiny amount of water or dirt in the lubricant can drastically reduce bearing operating life. Lip seals are primarily designed to keep lubricants in, and are not always effective at keeping contaminants out. The unique technology has been developed over a number of years to provide total bearing protection by ensuring zero leakage of lubricant to atmosphere and total exclusion of contaminants from the bearing housing.

0 kommentar(er)

0 kommentar(er)